Livestock Housing Ventilation: Natural Ventilation Design and Management for Dairy Housing

By Terry M. Mescher and Michael A. Veenhuizen, Ohio State University Extension

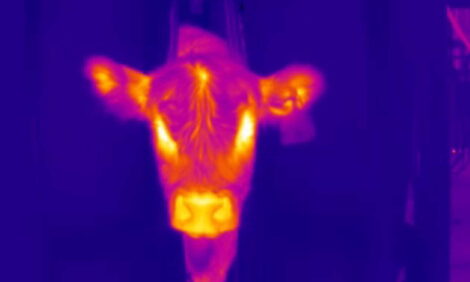

Ventilation systems in livestock housing serve an important function, maintaining a comfortable animal environment. Typically, a mature dairy cow will breathe out four to five gallons of water per day as water vapor and produce 2000 to 2400 BTU/hr or 600 to 700 Watts of heat. Ventilation systems continuously remove the heat, moisture, and odors created by livestock, and replenish the oxygen supply by bringing in drier, cooler outside air. Adequate air exchange also removes gases such as ammonia (NH4), hydrogen sulfide (H2S), and methane (CH4) which can be harmful to both animal and operator health.

Ventilation System Requirements

This factsheet provides an overview of the details and components needed in a properly sized natural ventilation system. The components of the ventilation system should provide the following basic features.- Air exchange. Sufficient air exchange is accomplished by the natural driving forces of wind and buoyancy.

- Control. Ventilation rates require adjustment based on inside and outside conditions. This is typically achieved with manually opened and closed curtains, doors, or ventilation panels.

- Flexibility. Ventilation needs based on different seasons require different operating conditions. At least three operating conditions must be provided.

- Continuous minimum air exchange is required to remove moisture constantly produced by the animals. This minimum air exchange is vital during sub-freezing weather.

- Temperature control which is needed during cool and mild weather conditions to remove excess heat from the building.

- High air exchange rates and air velocity past the animals is needed during hot weather to help remove heat from the cow's body.

- Continuous minimum air exchange is required to remove moisture constantly produced by the animals. This minimum air exchange is vital during sub-freezing weather.

- Proper barn construction. Naturally ventilated barns must have sufficient and properly located openings that can be adjusted to take advantage of buoyancy effects, as well as wind forces and direction.

The goals of a naturally ventilated dairy building in Ohio is to provide a winter shelter from wind, snow, and rain and a sunshade to reduce the cow's heat load during hot weather conditions. Typically, these barns are referred to as "cold barns" because they have little or no insulation and inside temperatures are usually within 10 degrees of outside temperatures. Minimum insulation (R-3 to R-5) under the roof can reduce inside surface temperatures on hot, sunny days. The comfort range for cows is between 32 degrees F and 77 degrees F.

It is not necessary to keep naturally ventilated dairy housing above freezing. Exposed milk and water lines are not required because cows are not washed or milked in these barns. Dairy cows are comfortable at lower temperatures and show very small declines in milk production if properly fed, protected from wind, precipitation, and provided a comfortable, dry place to rest. If these buildings are closed too tightly during cold weather, moisture and gasses will accumulate, condensation can occur, and poor air quality will result.

During hot weather conditions, a properly constructed dairy barn should act as a sunshade. Ventilation openings provide air movement past the animals to remove excess heat and reduce typical drops in milk production during extremely high temperatures. Circulating fans may be required during extremely hot weather to increase airflow across the cows.

Naturally Ventilated Building Components

Several key features and characteristics are required in a properly functioning natural ventilation system. These features include the building site, separation, and orientation; ridge or peak opening; eave or top sidewall openings; adjustable sidewall openings; and roof slope.The building site and orientation of a naturally ventilated dairy building must be determined early in the planning stage. Site the building on high ground and provide adequate separation (at least 50 feet) from other structures to reduce interference with airflow around and/or through the building. Provide at least a 100-foot separation from a wind break. Another important consideration is building orientation. Position the building with the long axis perpendicular to prevailing summer winds. Check local weather data for seasonal prevailing wind directions.

Several different ventilation openings are required to manage the building. These openings allow the operator to control the ventilation rate for different seasons or weather conditions. The following openings are recommended for different seasons.

A continuous ridge opening is needed for year-round ventilation control. The open ridge allows a chimney effect due to buoyant forces to be created, as well as creating a suction force while wind blows across the ridge. The opening acts as an exhaust to allow warm, moist air to exit the building. This is extremely important for winter ventilation when there is no cross ventilation through the building. This also allows for air movement through the barn on calm hot days when there is little or no cross ventilation due to wind.

During cold winter weather, a continuous air inlet opening that allows fresh air to enter the building is required. Locate the openings under the eaves or at the top of the sidewalls. Size openings equal to one half the ridge opening, and locate on both sides of the building. These openings need little or no adjustment. If the ridge or eave openings are closed or restricted, high humidity and condensation can occur, which creates an unhealthy animal environment and may accelerate building deterioration.

Adjustable sidewall openings are an important feature for mild winter, spring, and fall ventilation. Continuous 4-foot high sidewall openings above the cow level and adjustable endwall openings above cow level and traffic lanes can provide the air exchange required for temperature control during mild winter, spring, and fall weather. Mild weather ventilation is due to a combination of buoyancy and cross ventilation due to wind.

Additional sidewall openings and endwall openings at animal level provide cross ventilation through the animal zone, removing heat from around the cow and improving cow comfort. During the summer, the barn serves as a sunshade and rain shelter so complete or full wall openings are optimal. Sidewall closures may be curtains, hinged doors or windows, or removable panels.

Roof slope also affects the performance of a naturally ventilated building. A proper roof slope enhances air mixing within the building and the ventilation rate through the building. An ideal roof slope is 4:12 (rise:run). A shallow roof slope (less than 3:12) or a flat ceiling will reduce air movement due to buoyancy forces. This results in stagnant air spaces, reduced ventilation rate, and increased moisture, heat, gas, and odor accumulation. A steeper roof slope can enhance the upward air movement due to buoyancy, which increases the air exchange rate. However, roof slopes greater than 6:12 can cause incoming air to exit the building before mixing with inside air, resulting in poor air mixing in the animal zone, and pockets of damp, stale, warm air.

All components of a natural ventilation system are needed in newly constructed or remodeled buildings for successful year-round ventilation management. The following are some guidelines and construction tips for "cold" naturally ventilated dairy barns. Building Site

- Locate on high ground.

- Orient the long axis of the building perpendicular to prevailing summer winds.

- Provide adequate separation distance between buildings and other obstructions. Minimum 50-foot separation distance between buildings and 100 feet from wind breaks.

- Use a continuous open ridge. Provide 2 inches of width for every 10 feet of building width. For example, a 92-foot wide, 4-row, drive-through barn would require a minimum ridge opening of 20 inches.

- Protect structural members or trusses at ridge openings with flashing.

- Ridge caps are not usually recommended.

- Use a continuous eave opening or top of the wall opening. Provide half the ridge opening width (1 inch of width for every 10 feet of building width) on both sides of the building. For example, a 92-foot-wide barn requires a minimum eave opening of 10 inches in each sidewall.

- Sidewall and endwall construction must meet changing ventilation needs of winter weather and heat removal in hot weather.

- Full sidewall openings for summer ventilation.

- For mild weather ventilation, adjustable sidewall openings (4-foot continuous) above the cow level (about 4 feet above the floor).

- Sidewall height should allow for machinery access. Barns less than 40 feet in width should be 12 feet high. Barns wider than 40 feet should be 12 to 16 feet high. Higher sidewall height takes advantage of wind currents to increase air exchange and cooling during hot weather.

- Use a 4:12 to 6:12 (rise:run) roof slope for good air mixing in the animal zone. A 4:12 roof slope is preferred.

- Deep purlins (greater than 4 inches deep) tend to trap warm, moist air along the roof and may cause condensation to occur. Deep purlins should be covered to enhance airflow.

- Use positive bird protection. Bird elimination is difficult. Consider the following practices:

- Minimize roosting locations with blocking.

- Use plastic bird netting on ventilation openings and bottom of the trusses to exclude birds.

- Use clear-span arch construction rather than open trusses.

- Cover exposed insulation with solid barriers to prevent bird damage.

- Minimize roosting locations with blocking.

- When insulating the roof, use water-resistant, plastic-type insulation. Use a 4- to 6-mil polyethylene vapor barrier placed beneath insulation.

Naturally Ventilated Building Management

Management of a naturally ventilated building is as important to its operation as proper design. Proper management and adjustment of ventilation openings are important to assure cow comfort during three time periods: winter ventilation, summer ventilation, and spring/fall ventilation.Winter

- Ridge and eave inlets open.

- During severe winter weather air inlets may be partially closed. DO NOT CLOSE COMPLETELY.

- Sidewall and endwall openings closed and fastened.

- Ridge and eave inlets fully open.

- Upper sidewall and endwall openings adjusted to maintain a comfortable animal environment.

- Ridge and eaves open.

- Sidewalls and endwalls completely open to provide air movement in the animal zone.

Proper ventilation design and management practices apply to all stages of dairy production including newborn calves, replacement heifers, dry cows, and the milking herd. When planning or evaluating the ventilation system, the needs of the animals are most important. A properly designed and operating ventilating system provides an acceptable environment for the dairy animal and may not provide thermal comfort for barn workers. A cold, dry environment is better for the health and productivity of an animal than a warm, humid environment.

References

Bodman, Gerald R., "Non-Mechanical Ventilation-Designing for Function," Proceedings of the 2nd National Dairy Housing Conference, Madison, WI, ASAE, pp. 122-129.Dairy Housing and Equipment Handbook, MWPS-7, MidWest Plan Service, Ames, IA.

Graves, R. E. and M. F. Brugger, "Naturally Ventilated Freestall Barns," NRAES-77, pp. 409-417.

Veenhuizen, Michael A., "Providing a Healthy Environment with Proper Ventilation," NRAES-77, pp. 418-425.

December 2006