Dung Detective Takes Over From Fire Brigade

CYPRUS - Manure sieving is informing a Cyprus farm’s feed preparation, according to one of TheDairySite features this week.Extensive data from a milking robot is combined with a dung experiment to assess feed digestibility as part of a preventive approach to herd health. read more

This is somewhat of a new direction in Cyprus from the typical “fire-brigade” ideology to responding to problems, says a Cypriot nutritionist.

“I want to develop preventative programmes for the dairy farmers,” said Carolina Kyriacou, self-employed advisor. “Women advisers are pretty rare in farming. I am trying very hard to change this and am slowly but surely succeeding.”

Monthly body condition scoring; weekly and monthly fat and protein ratios; weekly, silage dry matter percentages; and daily dry matter intake, robot visits, rumination and ad libitum rumen pH are the monitoring tools she uses.

Her methods have brought about a 25 per cent yield increase in Christodoulos Kouloumbris’s 55 cow herd.

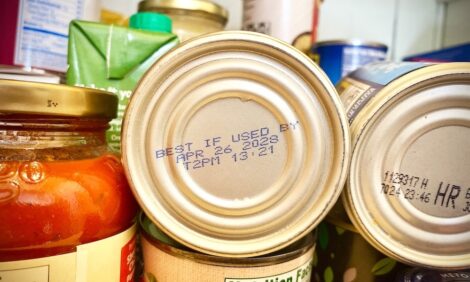

On inspecting dung samples, she explained: “Broken grain in the sieves shows that the hammer mill screens have holes in them, hence grains are not ground to the proper consistency.

“Finding long pieces of roughage in the sieves indicates that the chopper blades in the feed wagon are blunt and not providing a fine enough cut for the forages.”

Due to the extreme heat of the Cyprus summer, cows are kept inside in an open, airy shed, shading the herd from sunlight in 40 degree centigrade (104 F) heat. As a result, cows are zero-grazed as standard in what is essentially a Middle East climate. read more about the Cypriot industry here

Digestibility of feed is key for Mrs Kyriacou. The herd is fed corn and alfalfa silage, bought in from farms or grown on the 38 hectares the Kouloumbris family owns and some rented.

In the feature, contributing writer Stuart Lumb reveals that corn silage is prepared on a feed wagon and a pellet is produced on the farm for the robot.

“There is a feed mill on the farm but in addition a special concentrate pellet is purchased from a local feed mill," writes Stuart.

"The pellet is fed through the farm’s Lely robot at the rate of 5.5kg per day, enticing the cows in to be milked.”

He adds that attention to detail and dedication is paying off for Carolina in what is a very demanding industry.

Michael Priestley

News Team - Editor

Mainly production and market stories on ruminants sector. Works closely with sustainability consultants at FAI Farms