Idaho dairies turn manure into plastic, water and profit

New farm tech promises cleaner fields and better returnsIn southern Idaho’s dairy country, cow manure has long been both a costly challenge for farmers and a growing environmental concern. But a team backed by USDA’s National Institute of Food and Agriculture (NIFA) is now turning that waste into fertilizer, clean water and even biodegradable plastics, according to a USDA NIFA press release.

The Idaho Sustainable Agriculture Initiative for Dairy, or ISAID, has spent five years developing and testing systems that capture nutrients and byproducts from manure and wastewater. The research began in 2020 with a $10-million grant from USDA’s Sustainable Agriculture Systems Coordinated Agriculture Project.

Idaho, the third-largest dairy-producing state in the U.S., has climbed from 11th place just 25 years ago. But with that growth has come increasing pressure to manage the large volumes of liquid and solid manure generated by dairy farms.

A team led by the University of Idaho is now working to capture nitrogen and phosphorus from manure and convert them into valuable products, such as fertilizers and bioplastics. These can be used in other regions for crop production or as raw materials for manufacturing.

The project’s goal is to promote technologies that turn dairy manure into commercial fertilizers and value-added bioproducts, while improving soil quality, supporting farm productivity, cutting emissions, and creating new income and job opportunities.

Low-release fertilizer shows promise

One of ISAID’s key breakthroughs is “enriched biochar.” Researchers extract nitrogen and phosphorus from lagoon water and post-digester liquid, then infuse the nutrients into biochar — a charcoal-like substance. Once applied to fields, enriched biochar slowly releases nutrients over several months, reducing both fertilizer costs and runoff.

In greenhouse trials, vegetables and grains grown with enriched biochar performed as well or better than those treated with conventional fertilizers, said graduate student Samantha Clark, who leads the biochar greenhouse studies. “It’s remarkable how consistent the results are,” she said. “We see stronger root systems and more uniform growth, even when water is limited.”

A mobile treatment unit developed by ISAID partners will begin on-farm production of enriched biochar this fall, with larger field trials scheduled for the 2025 growing season.

Hydrochar captures phosphorus

Phosphorus, an essential but costly crop nutrient, is abundant in manure. Dr. Brian He’s team at the University of Idaho is using hydrothermal carbonization — essentially pressure-cooking manure — to create “hydrochar,” a dry, phosphorus-rich soil amendment.

“At the right temperature and pressure, we can trap up to 90% of the phosphorus in a stable form,” He said. “That cuts the risk of phosphorus runoff into waterways, which can trigger algae blooms, and gives farmers a reusable fertilizer source.”

Lab-scale reactors have identified optimal conditions at 200–220° C and 2–3 megapascals of pressure. This year, ISAID engineers will build a continuous-flow version for farm-scale use, while project economists complete a full cost–benefit analysis.

Plastics from barnyard byproducts

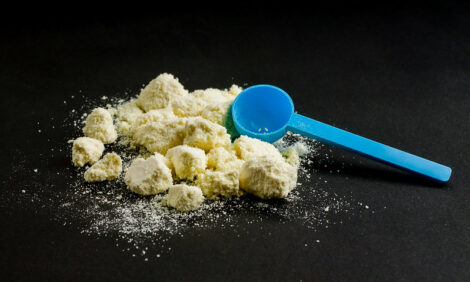

One of the more high-profile developments involves turning manure into biodegradable plastic. In a three-stage fermentation process led by soil and water engineer Dr. Erik Coats, bacteria consume volatile fatty acids from manure and convert them into polyhydroxyalkanoates (PHA) — a naturally occurring family of bioplastics.

“We’re seeing conversion rates over 60%, which rivals industrial bioplastic facilities,” Coats said. “And as a bonus, the process removes excess phosphorus, so you recover fertilizer and plastic at the same time.”

The team is now adjusting reactor settings to produce different types of plastic — from rigid packaging to flexible film — and conducting life-cycle analysis comparing the manure-derived plastics to conventional products.

Clean water recovery system

Water treatment is another focus area for ISAID. A prototype system, dubbed the “Clean Water Machine,” uses sedimentation, membrane filtration and advanced chemical processes to treat manure-laden wastewater. The result is water clean enough for irrigation and, with further polishing, potentially suitable for human use.

“Dairies use huge volumes of water, and disposing of nutrient-rich wastewater is expensive,” said extension engineer Lisa Martinez. “This system could let farms recycle up to 80% of their water, reducing costs and protecting rivers.”

A mobile lab trailer has been built to test the system on working farms. Field trials began in early 2024 and will continue through 2025.

Toward a circular dairy bioeconomy

Together, these technologies create the foundation for a circular dairy bioeconomy — one in which almost every component of manure and wastewater is recovered and reused. That could mean cleaner water, improved soils, reduced emissions, new products and new income.

“Imagine a dairy where you produce milk, sell biochar, sell phosphorus fertilizer, sell bioplastics and reuse your water,” said Jason Winfree, an agricultural economist with the University of Idaho who is leading ISAID’s market analysis. “That could radically change the financial outlook for family farms.”

Undergraduate and graduate students in agriculture and business have developed business and marketing plans for each product line. These include logistics, market research and pricing estimates, paving the way for potential spin-offs in rural Idaho.

Farmers ready to adopt

Local producers say they’re eager to see the innovations applied on their farms.

Third-generation dairy farmer Hank DeVries, whose family runs a 1,200-cow operation near Buhl, called the research “a game changer.”

“We’ve spread manure for years, but this could be a whole new industry born from milk production,” DeVries said. “Clean water, better fertilizer and maybe even plastic — it’s like turning waste into gold.”

At nearby Sunnyside Dairy, co-owner Jason Nunes agreed. “Manure is a renewable resource,” Nunes said. “If we can turn it into high-value products, that’s good for our business, good for the environment and good for the public perception of dairies.”

Training and outreach ongoing

ISAID’s outreach team is already sharing findings through bulletins, online tutorials and “The Clever Cow,” a podcast that explains each innovation.

In spring 2025, ISAID co-hosted a “Waste to Worth” conference with USDA in Boise, bringing together engineers, economists, producers and regulators to explore commercial adoption.

With on-farm trials, economic modelling and environmental monitoring continuing through 2025, ISAID researchers say decisions on adopting the new technologies will soon become easier.

“If the numbers add up, it won’t be a question of ‘Should we?’ but ‘How fast can we get started?’” Winfree said.