100,000 SCC: Why Not?

By Jeffrey K. Reneau, Department of Animal Science, University of Minnesota and presented at the University of Minnesota Dairy Days-2007.Why all the concern over bacteria and SCC?

SCC and bacteria counts are the universal indicators of milk quality. SCC is the indirect measure of udder infection. Individual cow SCC in 95% of uninfected cows will be less than 100,000. Bacteria counts are usually an indicator of sanitation (cows and milking equipment) and refrigeration capability. Occasionally, high bacteria counts can be the result of udder infections but usually they are the results of poor cow (udder) hygiene, inadequate milking equipment cleanup or inadequate refrigeration. A New York study (Boor et al.) of 844 dairy bulk tank standard plate counts indicated an average SPC of 11,400 cfu/ml. A similar Wisconsin study (Reinemann) found the average SPC to be 14,400 cfu/ml. Although the PMO legal standard is a SPC of 100,000 cfu/ml of milk, rarely do farm bulk tanks ever reach this very high level. SPCs that are above 25,000 cfu/ml represent a concern to processors and most dairies succeed in keeping bacteria counts below 10,000 cfu/ml.

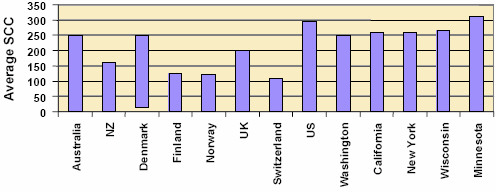

Generally speaking, high quality raw milk is free of all antibiotic or chemical residues, low in SCC (less than 200,000) and low in bacteria count (less than 5,000). These should be the minimum goals of every Minnesota dairy producer. During 2005, the average Bulk Tank Somatic Cell Count (BTSCC) of raw milk delivered to milk plants for processing from Minnesota dairies was 309,000, a significant improvement from 383,000 during 2002 at the beginning of the Minnesota Quality Count$ campaign. But we still have a long way to go. Most other milk producing countries in Europe as well as Australia and New Zealand already have national BTSCC averages near 200,000 or less. The 2005 U.S. average DHI SCC was 296,000. Of the top ten dairy states, Washington leads in milk quality with 249,000. Minnesota currently is 9th of the top 10 dairy states and 23rd ranked among all 50 states.

Why does raw milk quality matter? Milk quality is different than milk safety. All milk for human consumption must meet the minimum safety standards of 750,000 SCC and under 100,000 bacteria counts with no antibiotic or chemical residues. Public demand for improvement in milk quality beyond current milk safety standards is on the upswing. Why? For 25 years, dairy processors have recognized that high SCC significantly reduced cheese yields, texture and taste. Therefore, to encourage production of low SCC raw milk, Midwestern dairy processors have been paying quality premiums since 1979.

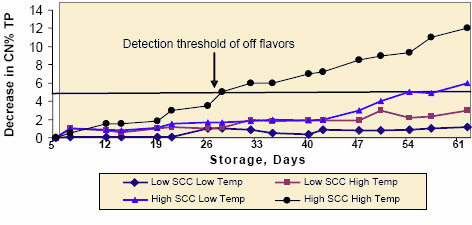

More recently, it has been recognized that raw milk quality has a dramatic effect on fluid milk taste and shelf life. The presence of high levels of SCC, bacteria or both will result in activating lipolytic and proteolytic enzymes that breakdown milk fat and protein resulting in off flavors and shorter shelf life. Since these enzymes are heat stable and not completely inactivated by pasteurization, milk protein and fat degradation continues even in refrigerated pasteurized products. Today pasteurized and properly refrigerated fluid milk has a dependable shelf life of approximately 3 weeks, beyond which undesirable off flavors may be detected. Dr. Dave Barbano and a team of Cornell researchers recently reported that it is possible to extend pasteurized fluid milk shelf life significantly by lowering SCC in milk. These researchers compared the difference in shelf life between very low (25,000) and high SCC milk (340,000). In their study, the 2% pasteurized low SCC milk was free of rancid (fat degradation) off flavor for 48 days longer than the high SCC milk. There was also a 25-day shelf life advantage in the appearance of bitter and astringent (protein degradation) off flavors in the low SCC milk. In addition, they tested the effect of storage temperature (see Figure 2). The detection of off flavors in the high SCC milk (340,000) stored at 43ºF occurred at 28 days but was delayed until 55 days when stored at 33ºF. The very low SCC (25,000) milk showed no signs of flavor deterioration at either storage temperature.

(Adapted from Barbano et al., JDS, 2006)

Why is longer shelf life necessary today? Trends in the current consolidation of the grocery and dairy processing businesses are resulting in longer food distribution chains. Food is being produced and processed longer distances from consumers. This means in order for future dairy products to remain “fresh” and acceptable to consumers, longer shelf life products will be required.

What will it take for us to reach future shelf life goals? Researchers currently speculate that with introduction of ultra filtration technology and improved refrigeration as well as a reduction of average SCC at the farm to 100,000, it will be possible to achieve pasteurized fluid milk with a shelf life of 60 to 90 days in the future. Wow! some of you may wonder… is consistent production of raw milk with SCC of 100,000 possible? The answer is yes. Many Minnesotan dairies are already achieving this level of performance.

How do the Swiss do it?

Switzerland is known for high quality. When we think of Swiss chocolate, watches, the Swiss Army knife whatever we always think of quality. They seem to have a quality mind set in whatever they do. It should be no surprise to us that the Swiss have the world’s highest quality milk. Since 1992, the national average SCC has been just over 100,000. The question is how do they do it?

We may say, "well they are just a small country with a few dairy herds so it is just easier." It is true that Switzerland is a small nation only about 1/5th the size in land area of Minnesota BUT they have 750,000 dairy cows and 42,000 dairy herds. Average herd size is small (17), production lower (12,000 lb/cow) and average milk price is higher ($26/cwt). Overall, the economic magnitude of the Swiss dairy industry is on par with Minnesota (2.2 billion dollars per year).

While smaller herd size and lower production with lots of pasture use may explain the low average SCC somewhat, this can’t be the whole story and it isn’t. Strong regulatory pressure has pushed their SCC down. Not only milk safety but also milk quality is regulated in Switzerland and there have been very strong penalties since 1973 for any milk over 350,000 SCC. This has motivated Swiss dairy producers to reduce herd mastitis levels (17% Swiss cows infected vs. 31.2% Minnesota cows infected) and divert high cell count milk from the bulk tank. This strategy has had a very dramatic impact. In 1980, the national SCC average was 171,000 and by 1992 it had decreased to slightly over 100,000 and has remained there since. In 1975, the percent of herds with SCCs > 350,000 was 17.5% and by 1989 it decreased to 4% where it has stabilized since that time.

Can SCC be too low?

Can SCC be too low and, if so, how low is too low? Some have worried that when herd SCC is low there will be more cases of clinical mastitis. Is this fact or fiction? Some recent research may help us to understand the answer to this concern.

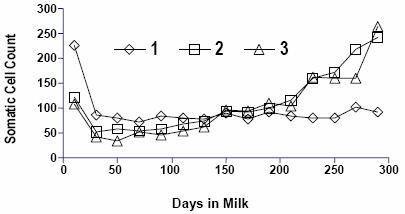

What is normal? In this study (Figure 3), 95% of uninfected cows had less than 100,000 SCC, except in the last months of lactation. Notice that uninfected 1st lactation cows had SCC levels near 50,000 or less.

(Schepers et al., JDS 1997)

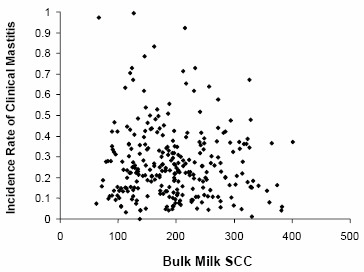

Under natural conditions, it appears that there would to be no correlation between herd SCC and clinical mastitis (see Figure 4). Low SCC herds experience no more clinical mastitis than high SCC herds.

So what’s the beef? A recent study in a single low SCC herd indicated that the very low SCC cows (those averaging 36,000) might be more vulnerable to mastitis infection when challenged by mastitis pathogens than cows with higher SCC (average 112,00). The question is, do the findings in this single herd apply to your herd circumstance?

The truth is that there probably is some somatic cell threshold under which a cow becomes more vulnerable to infection but it has not yet been determined. In addition, it needs to be remembered that it is more complicated than a simple matter of somatic cell number. Cell competence, the ability of somatic cells to kill invading bacteria, is equally important. It is well established that well balanced diets that meet the energy, vitamin and trace mineral requirements (in particular vitamin E and selenium) are needed to maintain an optimally functioning immune system.

So what’s the bottom line? Healthy well-fed cows with low individual SCC of 50,000 (maybe even less) do not appear to be more vulnerable to infection under natural conditions. Herd SCC counts of 150,000 or less are achievable and desirable for both cow health and productivity.

(Barkema et al., JDS, 1997)

How can we improve SCC in Minnesota?

You’ve heard all this before and these management practices are as valid today as they ever were:- Provide housing and bedding to keep cows (including dry cows) clean and dry.

- Make sure teat surfaces are thoroughly and consistently cleaned before each milking.

- Use fore-stripping to achieve good milk letdown and identify clinical mastitis cases.

- Divert milk from high SCC quarters away from the bulk tank.

- Achieve consistent and complete teat coverage when applying pre- or post-milking teat dip.

- Keep teat surfaces clean between milkings.

- Be sure that milking equipment is consistently cleaned and sanitized and operating correctly.

- Consistently store milk at less than 40ºF .

Notice that I have emphasized the word consistently. Many of you do follow these practices most of the time but quality milk depends on applying excellent management practices every day.

Recent Swedish research serves to re-emphasize the critical importance of pre-milking cow prep. These researchers compared the effectiveness of several teat-cleaning methods on cleaning experimentally contaminated teat surfaces. Ninety-six percent of all teat contamination was removed when the most intensive cleaning method was used (20 seconds cleaning and drying) regardless of the degree of teat contamination. Teat cleaning methods of lesser intensity resulted in only ~50% reduction of bacterial spores as compared to no prep. It is very important to note that their findings confirm our Minnesota experience that excellent pre-milking cow prep (20 seconds of cleaning and drying teats, including teat ends) goes a long way in reducing cell counts in spite of less than desirable cow cleanliness.

Minnesota dairy producers are just as smart and hard working as any. Therefore, if other dairy producing countries can produce milk with less than 200,000 SCC, we in Minnesota can do it too. For further details, you should check with your veterinarian, milk plant field staff or one of the Minnesota Extension Dairy Team members. Also, you can access the many milk quality fact sheets on the Dairy Extension website http://www.extension.umn.edu/dairy. Click on “Quality Count$”.

How do top milk quality Minnesotan dairies already achieve low SCC?

Milk quality surveys were mailed to 104 top milk quality DHI producers in Minnesota. These results will be shared at the Dairy Days presentation.

What’s the bottom line? If we are serious about increasing milk sales against competing beverages or about opening new marketing opportunities, we must improve raw milk quality at the farm and increase the shelf life of fluid milk. That’s a fact!

To view the references please click here.

List of Articles in this series

To view the complete list of 2007 Dairy Days reports click hereOctober 2007